Doors

Folding

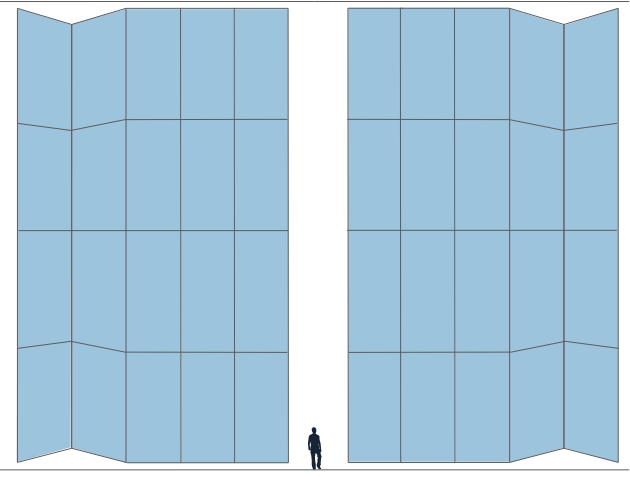

LARGE-SCALE FOLDING DOORS

Ideal for optimising spaces WITHOUT SACRIFICING VERSATILITY, adapting to any setting.

This type of door features vertical hinged panels that fold onto themselves, optimising the space available during opening. They are made with durable materials such as steel, iron, or insulated panels offering excellent thermal insulation and soundproofing.

Folding doors can be customised with windows, automation systems and specific finishes to suit a variety of aesthetic and operational requirements, ensuring practicality and long-lasting durability.

Hinged panels available in SUSPENDED or WHEELED configuration

Hinged-panel doors are ideal when maximum clearance is required and only limited space is available for leaf stacking.

Folding doors open by means of the leaves sliding and rotating into the stacking area.

The leaves can be:

- SUSPENDED from the upper guide, when the building has a sufficiently rigid supporting beam for the upper track (maximum deflection 20mm)

- supported ON CASTOR WHEELS.

The door can be motorised or operated manually.

FOLDING DOORS:

our solutions

With castor WHEELS

- Clear opening: Maximum width 50m per section / maximum height 15m

- Opening: Sliding and lateral stacking of leaves, guided at the top and supported on the ground by castor wheels

- Stacking: Single or double section, either outside the clear opening or within it, using cover panels.

- Panels: In a number proportional to the width of the doorway

- Speed: Opening/closure 10m/minute

- Execution: Motorised with electromechanical system

- Control panel: Electromechanical with electronic logic

- Control devices: Buttons on control panel

- Operating cycle: Hold-to-run

- Safety devices: Internal and external photocell safety barriers

- Signalling device: Flashing light and audible alarm

With SUSPENDED panels

- Clear opening: Width limited by the deflection of the support beam/maximum height 15m

- Opening: Sliding and lateral stacking of leaves suspended from the upper guide and guided on the ground.

- Stacking: Single or double section, either outside the clear opening or within it, using cover panels.

- Speed: Opening/closure 10m/minute

- Execution: Motorised with electromechanical system

- Control panel: Electromechanical with electronic logic

- Control devices: Buttons on control panel

- Operating cycle: Hold-to-run buttons (operator present)

- Safety devices: External and internal photocell barriers; electromechanical safety edge on the first leaf / central leaves

- Signalling device: Flashing light and audible alarm

CERTIFICATIONS

Certifications and compliance for LARGE-SCALE doors

Directive 2014/35/EU

On the harmonisation of the laws of the Member States relating to the making available on the market of electrical equipment designed for use within certain voltage limits.

Directive 2014/30/EU

On the harmonisation of the laws of the Member States relating to electromagnetic compatibility.

UNI EN ISO 12100:2010

Safety of machinery – General design principles – Risk assessment and risk reduction.

UNI EN ISO 13857:2020

Safety of machinery – Safety distances to prevent hazard zones being reached by upper and lower limbs.

UNI EN ISO 13854:2020

Safety of machinery – Minimum gaps to avoid crushing of parts of the human body.

CEI EN 60204-1:2018

Safety of machinery – Electrical equipment of machines. Part 1: General requirements.

UNI EN 12453:2017

Industrial, commercial and garage doors and gates – Safety in use of power operated doors – Requirements and test methods.

UNI EN 12604:2021

Industrial, commercial and garage doors and gates – Mechanical aspects – Requirements and test methods.

UNI EN 12635:2009

Industrial, commercial and garage doors and gates – Installation and use.